- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

Views: 41 Author: Site Editor Publish Time: 2023-09-04 Origin: Site

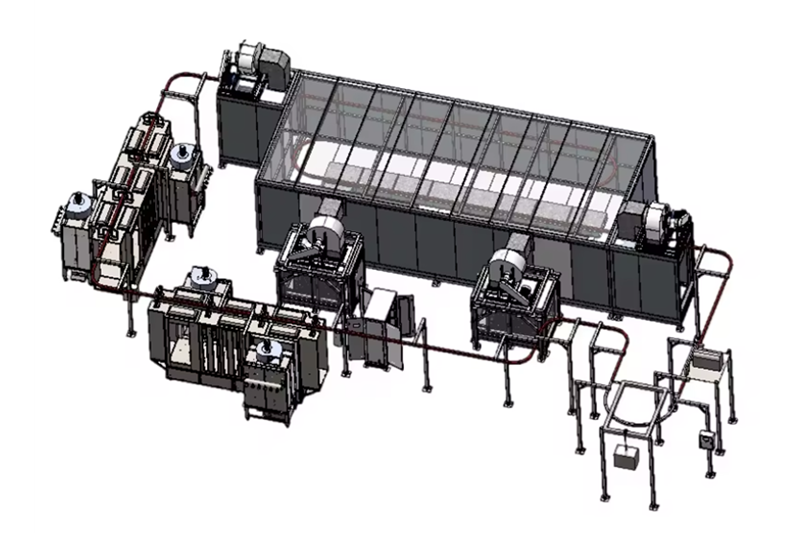

This automatic powder painting line is specially designed for our Mexico customer for the application of fan motor cover in high output (300 pcs per day).

As the customer mainly has 2 colors for application, we designed with 2 spray booths with powder coating equipment, one system works for one color. Thus the powder painting line has no need for cleaning during color change, greatly reduce downtime and increase working efficiency.

Workparts movement is driven through the overhead conveying system. When passing through an automatic spray booth, the workparts get powder spraying by automatic equipment ensures uniform powder film thickness. Afer spraying, the workparts will be automatically transported into a curing tunnel for continuously production.

Installation Key Data

Factory Size: L21m x W13m

Working Process, Fully Automatic

Production Capacity: 300pcs/day (8 hours)

Scope of Main Components

1. Automatic Powder Booth with Filter Recovery, 2sets

2. Automatic Powder Coating Reciprocator. 4sets

3. Automatic Powder Coating Guns, 16pcs

4. Powder Seiving Machine, 2sets

5. Manual Powder Coating Gun, 4sets

6. Tunnel Curing Oven, 1 set

7. Overhead Conveying System, 1 unit

Details of Main Components

Automatic Powder Coating Booth

1. Type: Pass through type, workparts are transpored to the booth by overhead conveyor and get spraying from both sides.

2. Working size: W1120*H2000*L4000mm, Opening: W800xH2000mm (standard model COLO-0825)

3. Working station: automatic coating station & manual coating station

4. Powder recovery: 2 filter cartridge recovery stages (12pcs) for each spray booth, Size: 325x900mm, 100% polyester

5. Fan motor: 5.5kw, 2 sets (for each booth)

6. Air flow 7000m³/h

5. Booth material: durable powder coated steel.

Automatic Powder Coating Equipment

1. Including: COLO-2000D reciprocator, COLO-191S automatic guns & central controlled cabinet

2. It is the ideal entry into automatic series production offering quality finishes and great powder savings.

3. Multi controllers of automatic powder coating gun installed on a central cabinet, with compact design and simple operation.

4. COLO-191S automatic powder coating machine is one of the most suitable solution for coating line, effective, reliable, cost-saving.

5. The 2m stroke reciprocator driven by frequency motor, speed and stroke adjustable.

Powder Curing Oven

1. Type: Tunnel type ovens are designed for continuous operations in automatic coating line.

2.Main Size: L8800 X W4300 x H2430 mm

3.Heating source: electric

4.Heating power: 3kw electric tubes of 180pcs

3. Heating Time & Temperature: Warm-up time: 15-30 min. (180° C), Max.250° C

4. Circulation Fan: 5.5kw, 2sets, creates uniform hot airflow in inner chamber ensure high quality curing results.

5. Construced with 100mm thickness rock wool board, ensures minium temperature dropping.

Powder Coating Conveyor System

1.Type: Overhead conveyor system for automatic powder coating line.

2. Total Length 74m

3. Hanging 2 point hanging

4. Chain Type: UH-5075-S.

5. Single Point Loading Capacity: 35kgs

6. Speed: 1.5m/min, adjustable

7. Other Components: Drive unit 1set, tension system 1set, urgent stop unit 4set.

We provide conveyor systems based on your specific products, designs varies from product weight, size and even the shape.