- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

Views: 32 Author: Site Editor Publish Time: 2023-09-04 Origin: Site

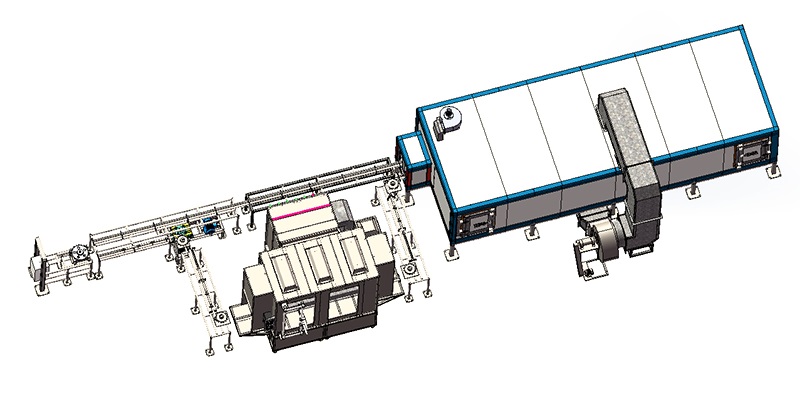

The ground rail automatic powder coating line is specially custom-designed for our Algeria customer for the application of metal themal cups. Cups are transported to an oven for pre-heating first, then pass into the spray booth recieving powder coat spraying, last enter to oven(the same oven of pretheating) for powder curing.

Project Key Data

Workpart: themal cups

Factory Size: L24 x W6.5m x H4.85m

Ground Rail Length: 125m

Round Rail Conveying Speed: 25m/min

Scope of Main Components

1. Filter Type Automatic Powder Booth

2. Automatic Powder Coating Guns

3. Powder Sieving & Recyling Machine

4. Powder Coating Oven for Pre-heating & Curing

5. Ground Rail Conveying System

Details of Main Components

Automatic Powder Coating Booth

1. Size: With1120 * Height1500 * Depth2900mm

2. Powder Recovery: Cartridge Filters, 4pcs, effectively collects powder overspray, ensures clean working environment and reduce powder waste.

3. Fan Motor: 1 set, 3kw 4500m3/h

4. Designed with working stations for automatic coating guns,

5. The automatic spray booth is controlled via PLC, which is easy for operation.

Automatic Powder Coating Equipment

1. Including 4 pcs COLO-800D automatic guns & central controlled cabinet

2. It is the ideal entry into automatic series production offering quality finishes and great powder savings.

3. Multi controllers of automatic powder coating gun installed on a central cabinet, with compact design and simple operation.

4. COLO-800D automatic powder coating machine is one of the most suitable solution for coating line, effective, reliable, cost-saving.

Powder Sieving and Recycling System

1.This system recycle large quantities of used powders without disturbing your online coating process, as weel as mix with fresh powders.

2.Breaking accumulations, sieving dusts, it continuously, uniformly feeds the powder to the spray gun, improves application quality.

3.Mounted with 100L capacity powder hopper that supports big production in continuous automatic line.

Tunnel Powder Coating Oven

1.Size: With2300 * Height1100 * Depth14600mm

2. Heating Power Electric, 252KW, features easy structure, simple operation & maintenance

3. Heating Time & Temperature: Warm-up time: 15-30 min. (180° C), Max.250° C

4. Circulation Fan: 5.5kw, 2sets, creates uniform hot airflow in inner chamber ensure high quality curing results.

5. Construced with 100mm thickness rock wool board, ensures minium temperature dropping.

The fully automatic complete powder coating line minimizes labor cost, ensures high production and uniform quality. Workparts movement by automatic ground conveying system. which deal for powder coating metal cups, cans or bottles which are not able to be suspended by overhead conveyors.