- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

Views: 31 Author: Site Editor Publish Time: 2023-09-04 Origin: Site

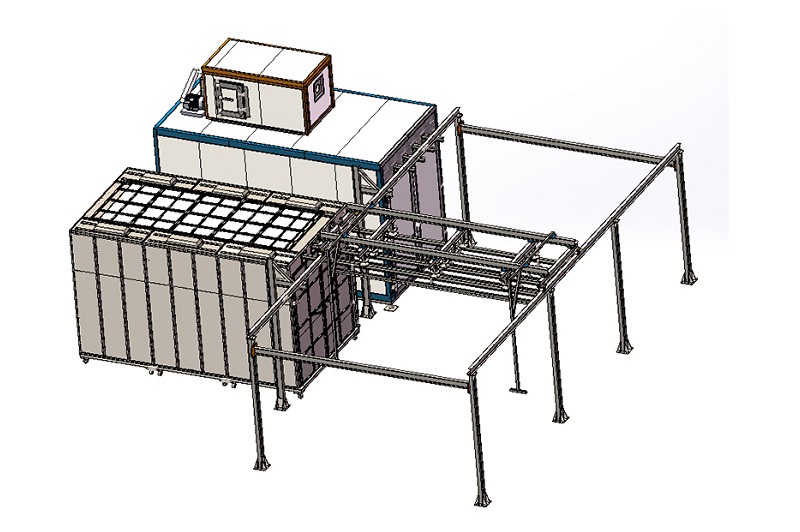

The manual powder coating plant is specially custom-designed for our Australia customer for the application of big volume brackets and other large metal parts.

Powder coating by manual coating equipment ensures high precision operation, especially for complex shaped. Workparts movement from booth to curing oven by manual-pulled track system, thus reduces labor efforts and saves factory space.

Project Key Data

Workpart: Metal Brackets, Frames, Plates, Cabinets,

Factory Size Requirement: More than L14xW12m

Main Components

1. Manual Powder Coating Machineq

2. Walk-in Powder Coating Biooth

3. Gas Powder Coating Oven

4. Manual Operated Overhead Track System

before

after

after

Details of Main Components

Manual Powder Coating Booth

Walk-in powder spray booth, allows big dimension workparts entering the booth through the overhead rail system, powder coating by manual equipment with precise operation. COLO powder coating ensures high powder recycling rate and clean working condition.

1.Working Size: L5.5m x W2.8m x H3.1m

2.Opening Size: W2.8m x H2.9m

3. Recovery unit: including 12pcs high precsion cartridge filters

4. Fan Motor: 3kw, 4 sets, 5000m^3/h

5.Material: SPCC/t=1.5mm.

6. Control: PLC

Track Powder Coating Oven

The powder coating ovens with overhead rail system is designed in order to carry heavy material into the oven manually. COLO curing oven is built to create optimal airflow throughout the enclosure, providing an even, constant cure for your parts.

Specifications

1. Working Size W 2.5m x H 3.1m x D 5.6m

2. Heating source: Natural Gas

3. Gas Burner: 300,000 kcal/h, RIELLO brand

3. Circulation Fan: 11kw, 1 set, 12000m^3/h

4. Thermal Insulation Material 100mm thickness rock wool board.

5. Temperature: 180°C - 250°C