- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

Views: 39 Author: Site Editor Publish Time: 2023-09-04 Origin: Site

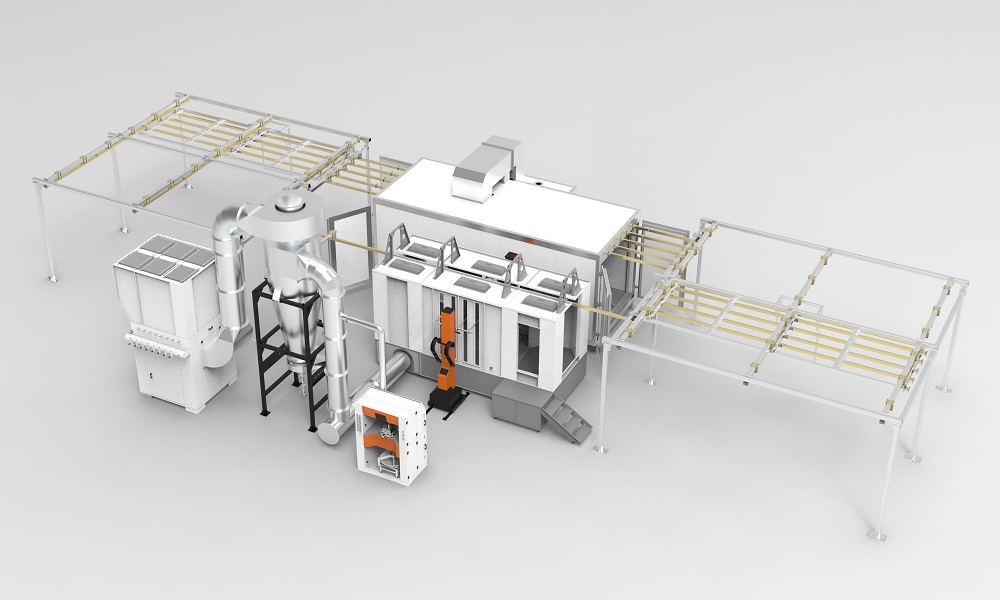

The semi-automatic powder coating line is specially custom-designed for our Ethiopia customer for the application of steel chairs, aluminum profiles, or ther metal furnitures.

Powder coating by automatic ensures high production and uniform quality, workparts movement from booth to curing oven by manual operated track system, thus requires smaller factory space and and less budget.It is ideal for powder coating big, heavy or long length metal parts.

Installation Key Data

Workpart: Chairs, Aluminium Profiles, Furniture Products

Max.Part Size: L1.5xW0.7xH2m

Factory Size: L30x15m, Heigt more than 5m

Scope of Main Components

1. Cyclone Automatic Powder Booth for Fast Color Change

2. Automatic Powder Coating Reciprocator

3. Automatic Powder Coating Guns

4. Manual Powder Coating Gun

5. Powder Sieving & Recyling Machine

6. Electric Powder Coating Oven

7. Manual Operated Overhead Track System

Details of Main Components

Automatic Powder Coating Booth

1. Working Size W800*H5000*L3000mm

2. First stage recovery: Mono cyclone type, maximize cleaning efficiency during color change, achieves recycling efficiency up to 98%, a great saving of powders.

3. Secondary recovery stage: a group of high precision filters effectively capture ultra fine powders, thus only particle-free air discharged outside.

4.Booth Floor cleaning system: air cleaning, transfer sprayed powder from the booth floor to recycling system

5. Booth material: durable stainless steel.

Automatic Powder Coating Equipment

1. Including: COLO-2000D reciprocator, COLO-800D automatic guns & central controlled cabinet

2. It is the ideal entry into automatic series production offering quality finishes and great powder savings.

3. Multi controllers of automatic powder coating gun installed on a central cabinet, with compact design and simple operation.

4. COLO-800D automatic powder coating machine is one of the most suitable solution for coating line, effective, reliable, cost-saving.

5. The reciprocator driven by frequency motor, speed and stroke adjustable.

Track Powder Coating Oven

1.Working Size 6.5mx2.18mx2.54m

2.Heating source: electric, features easy structure, simple operation & maintenance

3. A powerful circulation fan makes uniform hot airflow in inner chamber ensure high quality curing results.

4. Construced with 100mm thickness rock wool board, ensures minium temperature dropping.

5. PLC control system provides an easy and accurate heating process, digitally setting the heating time and temperature.