- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

Views: 22 Author: Site Editor Publish Time: 2021-11-10 Origin: Site

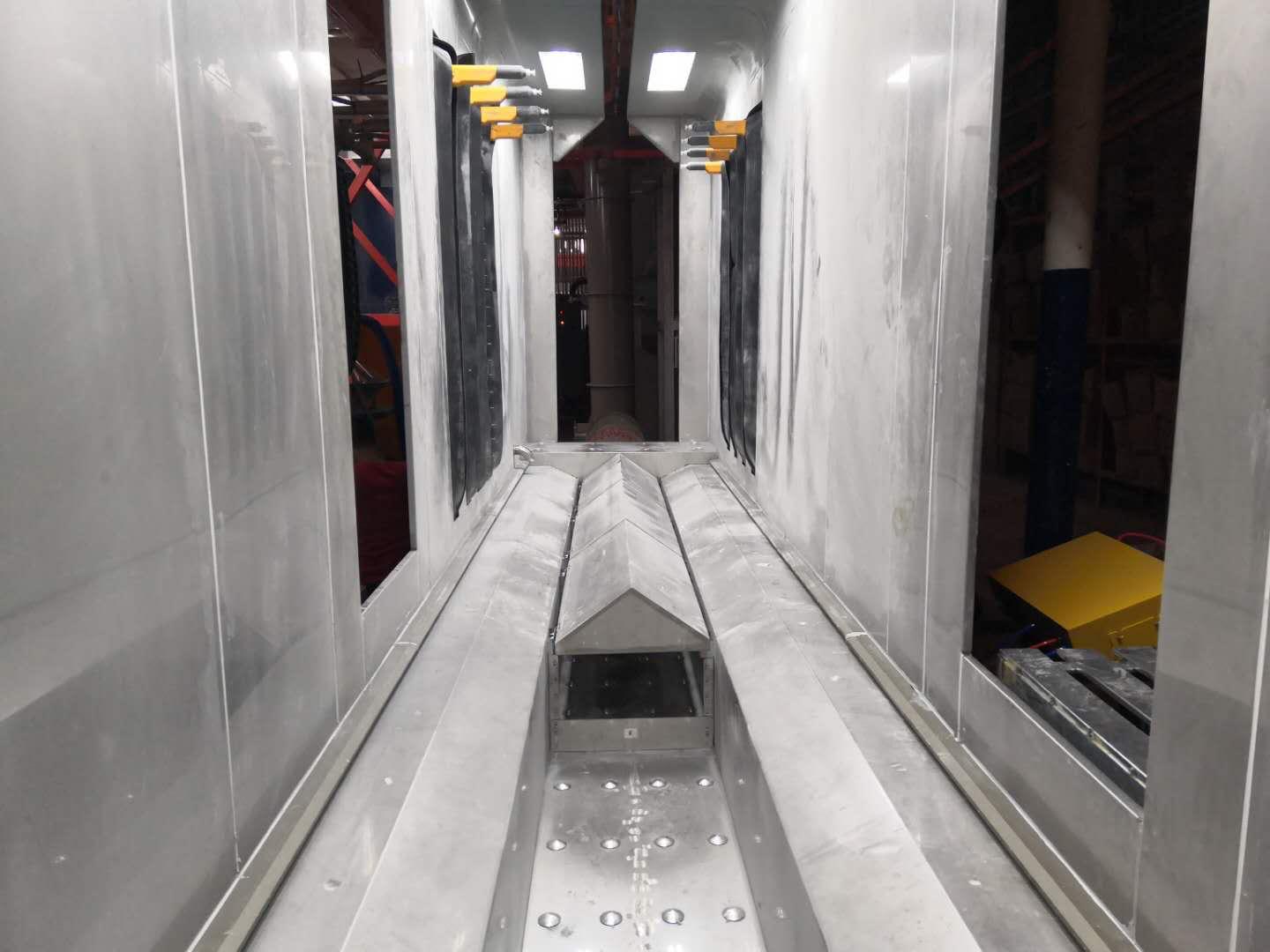

During powder coating operations, some people find their powder coating booth drift out of powders from the opening,there are some reasons that can cause this problem, you can find the solutions refer to the below reasons according to your booth situations:

Possible Causes & Solutions

1) Not enough containment air flowing through the powder booth and recovery system. Check the blower, and if the fan blower can not create sufficient air flow then will cause the powder flying out of the booth everywhere.

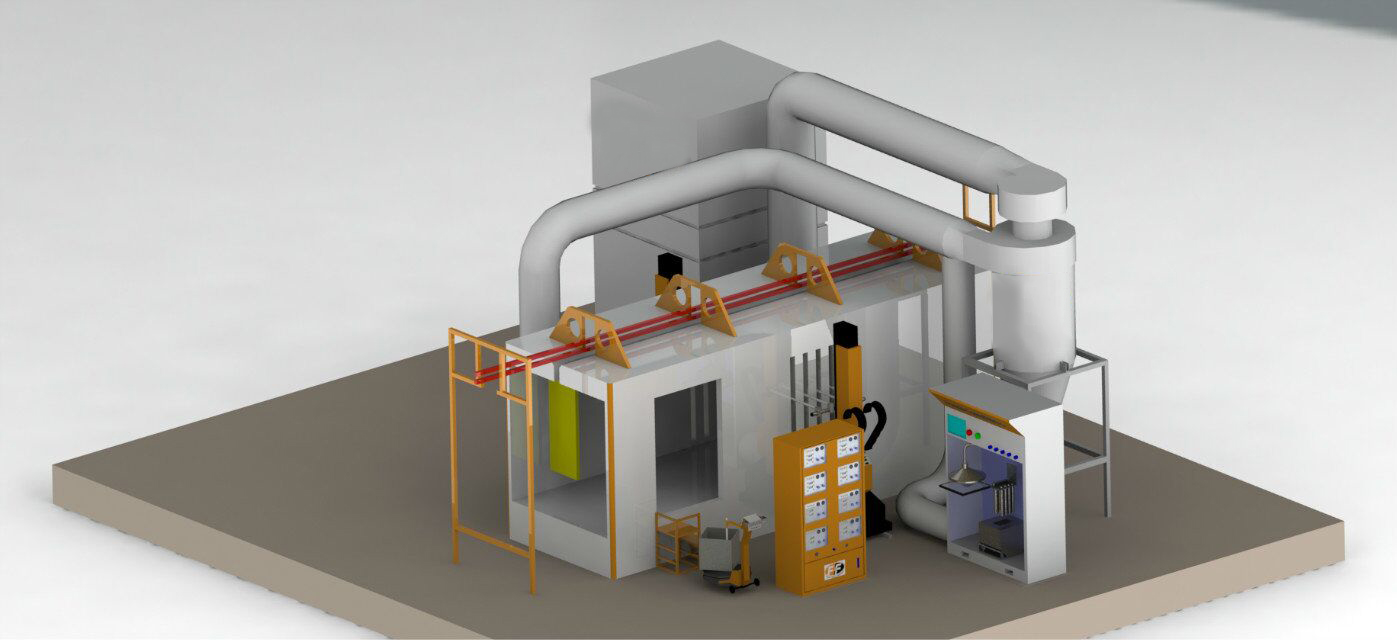

2) Cyclone specification is too small to reach an ideal powder separation capacity, Cyclone unit directly attaches to the booth, which handles all of the exhausted air from the booth and separates particles based on size for further filtration.

3) Filters not receiving adequate cleaning. Increase pulse air pressure or volume.

4) Cartridge filters nearing the end of their expected life. Changed the filters to the new, normaly quality filters has about 2~3 years lifespan, superior quality filter has about 5 year lifespan.

4: Final filters becoming clogged. Note that final filter clogging may be related to poor upstream seals or leakage of powder in the recovery.

If you're looking for the new quality powder coating filters, fan blowers, cyclone recovery or whole powder spray booth system, you can contact us, we have 10 years experience in designing and manufacturing powder coating equipment.

Sales & Technical Support:

Email: cologroup@colourspray.com

Whatsapp: 0086 18069805616