- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

COLO-668A

COLO

| Availability: | |

|---|---|

| Quantity: | |

COLO-668 Central Cabinet for Automatic Powder Guns

Multi controllers of COLO-668-A automatic powder coating guns installed on a central cabinet, features compact design and simple operation

1. Automatic gun spraying parameters can be controlled quickly and easily with different jobs,

2. Support for custom, up to 24 powder gun controllers could be installed on the cabinet.

3. Work with COLO reciprocators offering quality finishes, large powder savings and a quick payback

4. Particularly suitable for users who switch from manual application to automatic powder coating.

Voltage can be flexibly adjusted from 0-100kv, the values will be shown on the digital display for accurate reading.

Designed with intelligent one-touch bottons, switch for 4 preset application programs:

1. Flat coating for simple and flat shape parts.

2. Corner coating for parts with complex shape and deep corners.

3. Recoating for repairing powder coating parts.

4. Pulse coating, repidly recharge the powder for high transfer efficiency, reduces orange peel effect efficiently.

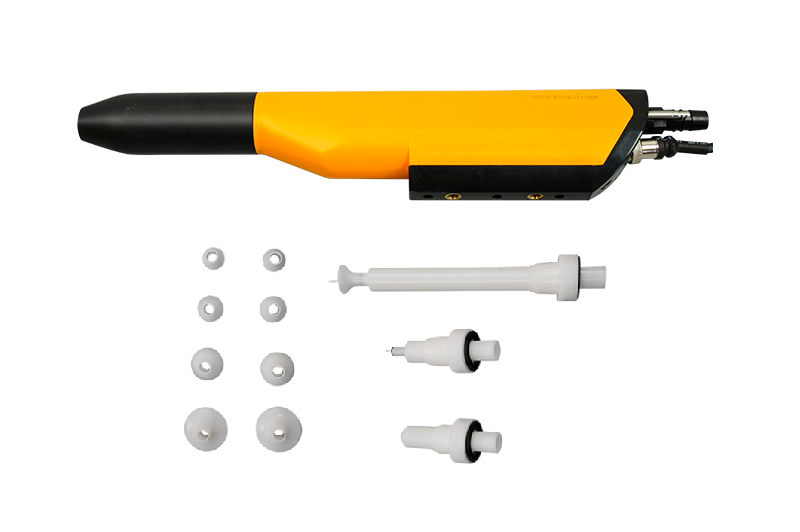

COLO-08 Automatic Spray Gun Features

COLO-08 Automatic Spray Gun Features

1. Lightweight, compact gun provides 100 kV and the highest transfer efficiency available for venturi-based coating systems.

2. With the COLO unique-designed spray gun, finishers can achieve superior powder coating coverage.

3. Air-purge cleanable design for fast, easy cleaning, without gun disassembly, a requirement for all quick color change applications

4. Superior Faraday-cage penetration and recoating capability to adapt a wide range of coating challenges

COLO-668 Central Cabinet for Automatic Powder Guns

Multi controllers of COLO-668-A automatic powder coating guns installed on a central cabinet, features compact design and simple operation

1. Automatic gun spraying parameters can be controlled quickly and easily with different jobs,

2. Support for custom, up to 24 powder gun controllers could be installed on the cabinet.

3. Work with COLO reciprocators offering quality finishes, large powder savings and a quick payback

4. Particularly suitable for users who switch from manual application to automatic powder coating.

Voltage can be flexibly adjusted from 0-100kv, the values will be shown on the digital display for accurate reading.

Designed with intelligent one-touch bottons, switch for 4 preset application programs:

1. Flat coating for simple and flat shape parts.

2. Corner coating for parts with complex shape and deep corners.

3. Recoating for repairing powder coating parts.

4. Pulse coating, repidly recharge the powder for high transfer efficiency, reduces orange peel effect efficiently.

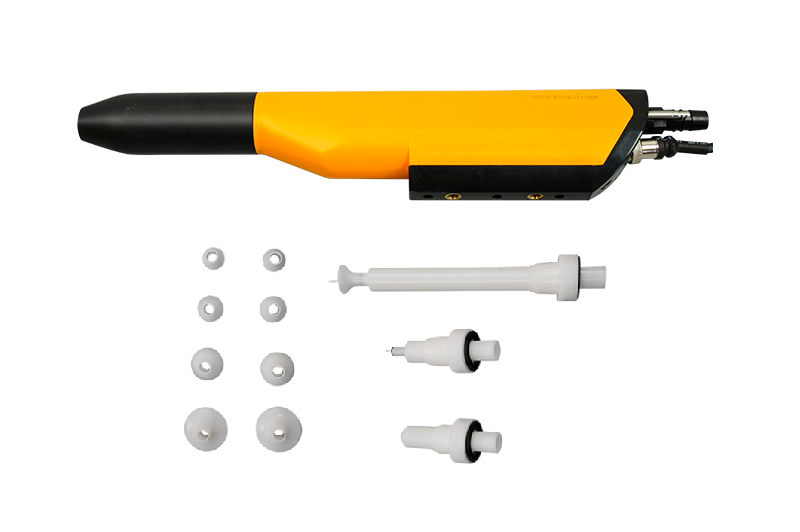

COLO-08 Automatic Spray Gun Features

COLO-08 Automatic Spray Gun Features

1. Lightweight, compact gun provides 100 kV and the highest transfer efficiency available for venturi-based coating systems.

2. With the COLO unique-designed spray gun, finishers can achieve superior powder coating coverage.

3. Air-purge cleanable design for fast, easy cleaning, without gun disassembly, a requirement for all quick color change applications

4. Superior Faraday-cage penetration and recoating capability to adapt a wide range of coating challenges