- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

COLO-191S-A

COLO

| Availability: | |

|---|---|

| Quantity: | |

COLO-2200D powder coating reciprcator carries spray guns in automatic line, giving gentle and precise motion, ensuring uniform coating result with great powder savings.

1. Extremely smooth movement through low noise and wear-resisting belt transmission.

2. Precise speed, stroke and position you can set on the PLC controller by touch screen.

3. Different job selection from 20 strorable programs, muilti languages for choice.

4. Steady construction and running provide more unifom and quality finish

5. Allows to install up to 24 pcs spray guns with high stability.

COLO-191S-A Automatic Powder Coating Guns Control Cabinet

It is the ideal entry into automatic series production offering quality finishes and great powder savings.

1. A module in powder coating line which could be easily tailored to customer's demands.

2. The cabinet network could carry up to 24 controller, all parameters can be set on a host controller.

3. Get typically excellent finishes with consistent uniform film thickness.

4. Most suitable for high speed converised powder coating lines.

5. Integrate with COLO reciprocators offering quality finishes, large powder savings and a quick payback

COLO-191S Powder Gun Controller

1. Developed by COLO experts with patented design makes superior-quality surface finish.

2. Offers 3 pre-set standard application programs for flat parts, profiles and recoating.

2. Allows to create and store 20 personalized application programs for different parts and powder.

3. Voltage and current can be separately set in order to optimize the powder coating application.

4. Digital valve control technology supports precise adjustment of pneumatic data that ensure perfect atomization and powder output.

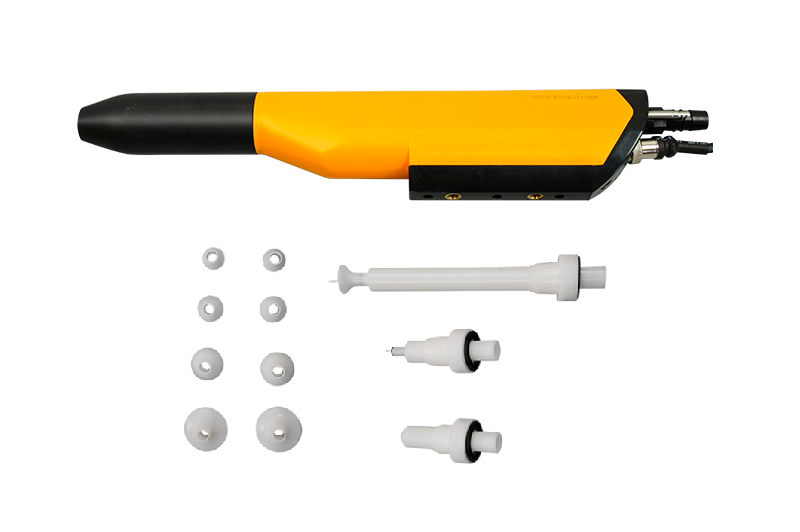

COLO-08 Automatic Spray Gun Features

COLO-08 Automatic Spray Gun Features

1. Lightweight, compact gun provides 100 kV and the highest transfer efficiency available for venturi-based coating systems.

2. With the COLO unique-designed spray gun, finishers can achieve superior powder coating coverage.

3. Air-purge cleanable design for fast, easy cleaning, without gun disassembly, a requirement for all quick color change applications

4. Superior Faraday-cage penetration and recoating capability to adapt a wide range of coating challenges.

The automatic powder coating plant is in Austrailia customer's factory customer for the application of springs. The plant includes automatic coating equipment and reciprocators, mono-cyclone recovery booth, automatic conveyor system suitable for high production rate and minimum labor cost.

COLO-2200D powder coating reciprcator carries spray guns in automatic line, giving gentle and precise motion, ensuring uniform coating result with great powder savings.

1. Extremely smooth movement through low noise and wear-resisting belt transmission.

2. Precise speed, stroke and position you can set on the PLC controller by touch screen.

3. Different job selection from 20 strorable programs, muilti languages for choice.

4. Steady construction and running provide more unifom and quality finish

5. Allows to install up to 24 pcs spray guns with high stability.

COLO-191S-A Automatic Powder Coating Guns Control Cabinet

It is the ideal entry into automatic series production offering quality finishes and great powder savings.

1. A module in powder coating line which could be easily tailored to customer's demands.

2. The cabinet network could carry up to 24 controller, all parameters can be set on a host controller.

3. Get typically excellent finishes with consistent uniform film thickness.

4. Most suitable for high speed converised powder coating lines.

5. Integrate with COLO reciprocators offering quality finishes, large powder savings and a quick payback

COLO-191S Powder Gun Controller

1. Developed by COLO experts with patented design makes superior-quality surface finish.

2. Offers 3 pre-set standard application programs for flat parts, profiles and recoating.

2. Allows to create and store 20 personalized application programs for different parts and powder.

3. Voltage and current can be separately set in order to optimize the powder coating application.

4. Digital valve control technology supports precise adjustment of pneumatic data that ensure perfect atomization and powder output.

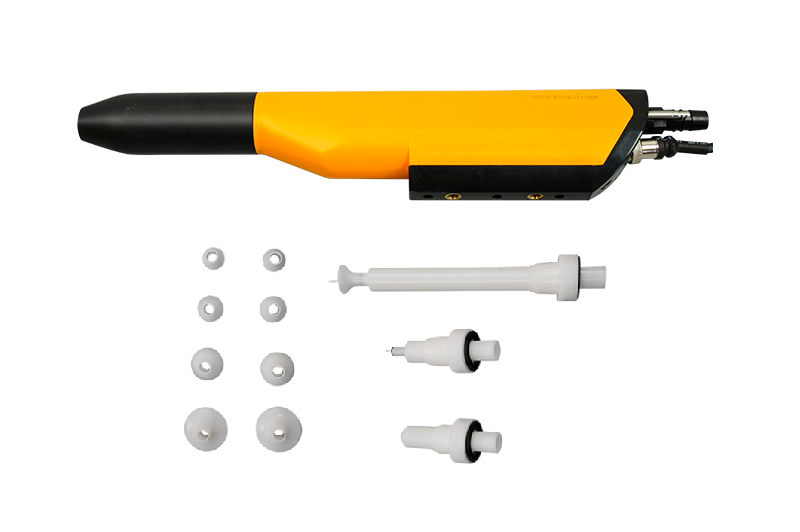

COLO-08 Automatic Spray Gun Features

COLO-08 Automatic Spray Gun Features

1. Lightweight, compact gun provides 100 kV and the highest transfer efficiency available for venturi-based coating systems.

2. With the COLO unique-designed spray gun, finishers can achieve superior powder coating coverage.

3. Air-purge cleanable design for fast, easy cleaning, without gun disassembly, a requirement for all quick color change applications

4. Superior Faraday-cage penetration and recoating capability to adapt a wide range of coating challenges.

The automatic powder coating plant is in Austrailia customer's factory customer for the application of springs. The plant includes automatic coating equipment and reciprocators, mono-cyclone recovery booth, automatic conveyor system suitable for high production rate and minimum labor cost.