- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

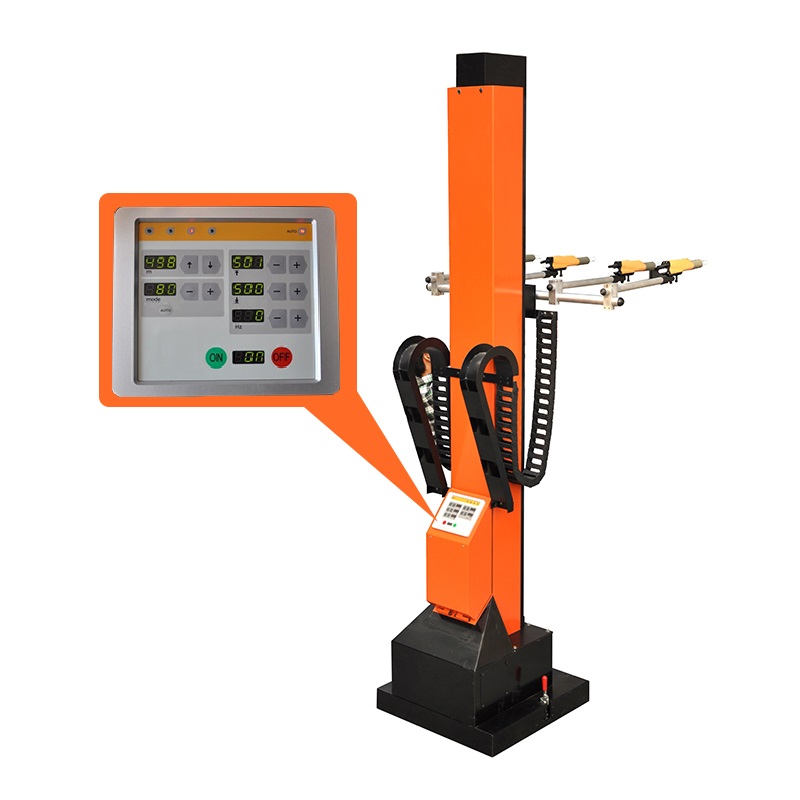

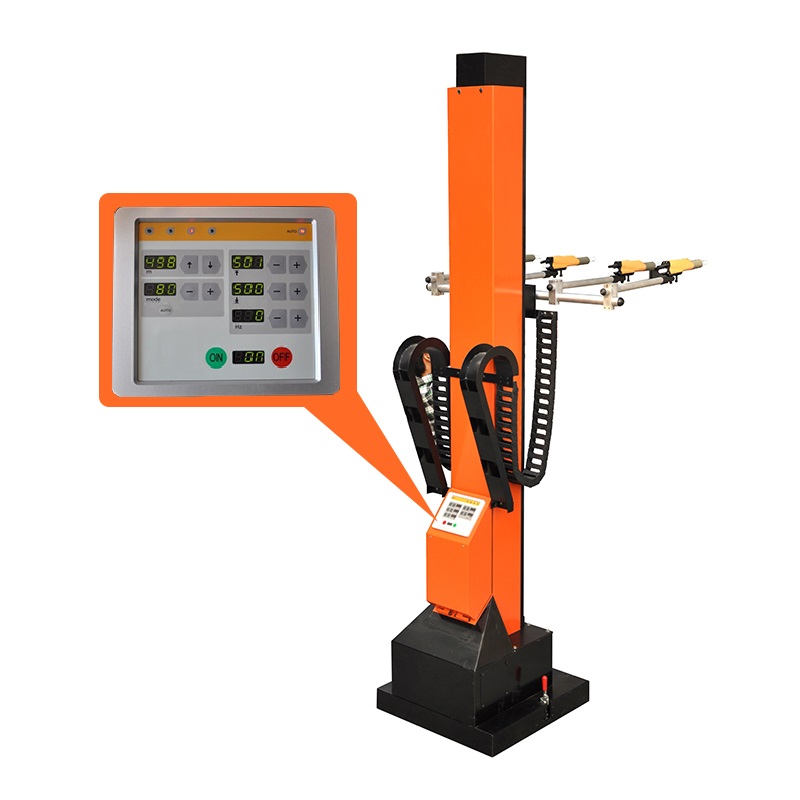

COLO-L-M06

COLO

| Availability: | |

|---|---|

| Quantity: | |

Semi-automatic powder coating line includes automatic powder coating system, automatic booth system, automatic powder recycling system and a manual batch curing oven. We provide professional service of powder coating line designing, manufacturing, assembling, commissioning and training for oversea countries

1. Usually applies cyclone powder booth achieves high recycling rate and quick cleaning operation during color change lines.

2. The secondary recovey stage is combined with a group of high precision filters effectively capture ultra fine powders, thus only particle-free air discharged outside.

3. There's air clean system continuously transports over sprayed powder from the booth floor, quickly recycling it back to the powder supply center.

4. Booth material can be made coated steel, stainless steel, or enginner plastic, while the plastic booth is highly recommended for more powder recyling and cleaner condition.

.

1. A central cabinet combines all powder coating gun controllers for integrated operation.

3. The COLO-800D powder coating unit applies latest technology for easiest operation, giving perfect finish with consistent quality, whether for panels or complex shapes.

4. The 100kv spray gun delivers high transfer efficiency, increase powder utilization and reduce waste

5. Tested reliable system based on COLO over 10 years manufacturing experience.

COLO Reciprocator is designed for consistent and uniform coating in automatic production line. spraying guns movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

Features

1. Working parameters are monitored on a user-friendly panel,

2. The digital control system can be memorized for 80 storable programs

3. Allows to carry 2-12pcs spray gun, making smooth movement

4. Driven by frequency motor, solid and maintenance free.

5. Sturdy construction could adapt to continual load everyday operational conditions.

1. Allows directly placing the powder carton on a funnel, flexible for color change.

2. Automatic cleaning of spray guns, powder hoses, injectors during color change, reduce manpower and increase efficiency.

3. Ultrasonic sieving of fresh powders and recovery powders, dissolving and loosening of powder accumulations for even powder flow.

4. A built-in closed powder hopper with a senser will detect the powder position and alarm a signal when a lack of powder, ensure continuous powder feeding.

5. A user-friendly PLC touching screen panel makes it easy to handle the process

1.Curing oven is made of 100mm rock wool board with galvanized steel wall, features durable and heat-resistent.

2.Quickly and uniformly raise to required temperature up, increase production efficiency

3.With fan that circles hot air through the entire chamber ensures even temperature.

4.Heating source can be electric, gas or diesel. Gas oven is more recommended to save energy expense.

5. An economical transport system includes an upper loading frame and lower carrige that requires you minimum force to handle batch of heavy workparts

Semi-automatic powder coating line includes automatic powder coating system, automatic booth system, automatic powder recycling system and a manual batch curing oven. We provide professional service of powder coating line designing, manufacturing, assembling, commissioning and training for oversea countries

1. Usually applies cyclone powder booth achieves high recycling rate and quick cleaning operation during color change lines.

2. The secondary recovey stage is combined with a group of high precision filters effectively capture ultra fine powders, thus only particle-free air discharged outside.

3. There's air clean system continuously transports over sprayed powder from the booth floor, quickly recycling it back to the powder supply center.

4. Booth material can be made coated steel, stainless steel, or enginner plastic, while the plastic booth is highly recommended for more powder recyling and cleaner condition.

.

1. A central cabinet combines all powder coating gun controllers for integrated operation.

3. The COLO-800D powder coating unit applies latest technology for easiest operation, giving perfect finish with consistent quality, whether for panels or complex shapes.

4. The 100kv spray gun delivers high transfer efficiency, increase powder utilization and reduce waste

5. Tested reliable system based on COLO over 10 years manufacturing experience.

COLO Reciprocator is designed for consistent and uniform coating in automatic production line. spraying guns movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

Features

1. Working parameters are monitored on a user-friendly panel,

2. The digital control system can be memorized for 80 storable programs

3. Allows to carry 2-12pcs spray gun, making smooth movement

4. Driven by frequency motor, solid and maintenance free.

5. Sturdy construction could adapt to continual load everyday operational conditions.

1. Allows directly placing the powder carton on a funnel, flexible for color change.

2. Automatic cleaning of spray guns, powder hoses, injectors during color change, reduce manpower and increase efficiency.

3. Ultrasonic sieving of fresh powders and recovery powders, dissolving and loosening of powder accumulations for even powder flow.

4. A built-in closed powder hopper with a senser will detect the powder position and alarm a signal when a lack of powder, ensure continuous powder feeding.

5. A user-friendly PLC touching screen panel makes it easy to handle the process

1.Curing oven is made of 100mm rock wool board with galvanized steel wall, features durable and heat-resistent.

2.Quickly and uniformly raise to required temperature up, increase production efficiency

3.With fan that circles hot air through the entire chamber ensures even temperature.

4.Heating source can be electric, gas or diesel. Gas oven is more recommended to save energy expense.

5. An economical transport system includes an upper loading frame and lower carrige that requires you minimum force to handle batch of heavy workparts

The COLO manual batch powder coating plant built in Thailand.

The COLO manual batch powder coating plant built in Thailand.