- Home

- About Us

- Products

- Solutions

- Case Study

- Videos

- Support

- Contact Us

COLO

| Availability: | |

|---|---|

| Quantity: | |

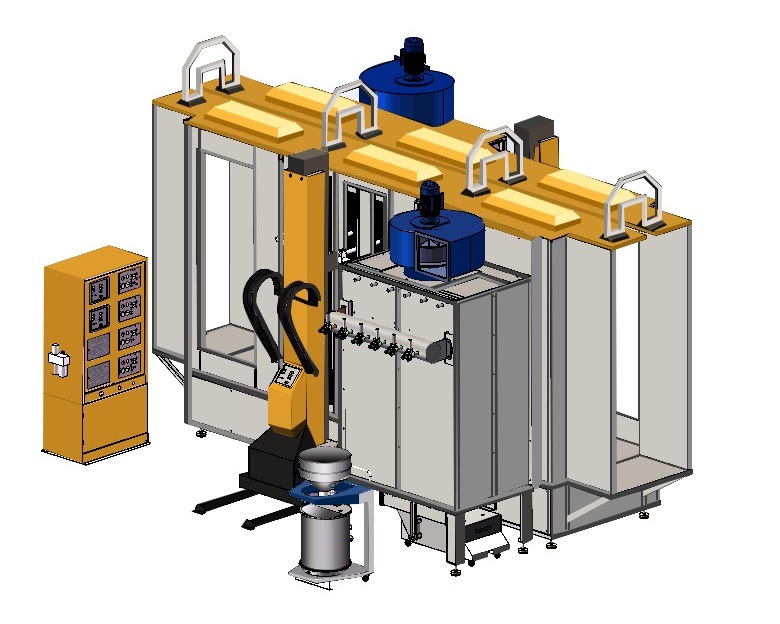

Powder coating booth with spraying system a highly-efficient solution in automatic powder coating line. Reciprocators and automatic powder guns ensures productivity and uniformity, Automatic spray booth with powder recycling system creates clean working condition with high powder utilization rate. It is ideal for high production of aluminium profiles, steel plates, frames, metal furniture products with single color application.

1. Designed with double automatic station for reciprocator powder coating and double manual station for repair coating.

2. Two groups of cartridge filter ensures effective recovery of oversprayed powders.

3. Pulse-jet automatic filter cleaning technology takes full utilization of powders and extent filter life for many years.

4. All functions, parameters can be flexiblely controlled on the PLC panel, such as fan start, filter cleaning, booth cleaning.

5. Can be connected with powder management equipment for automatic powder recycling.

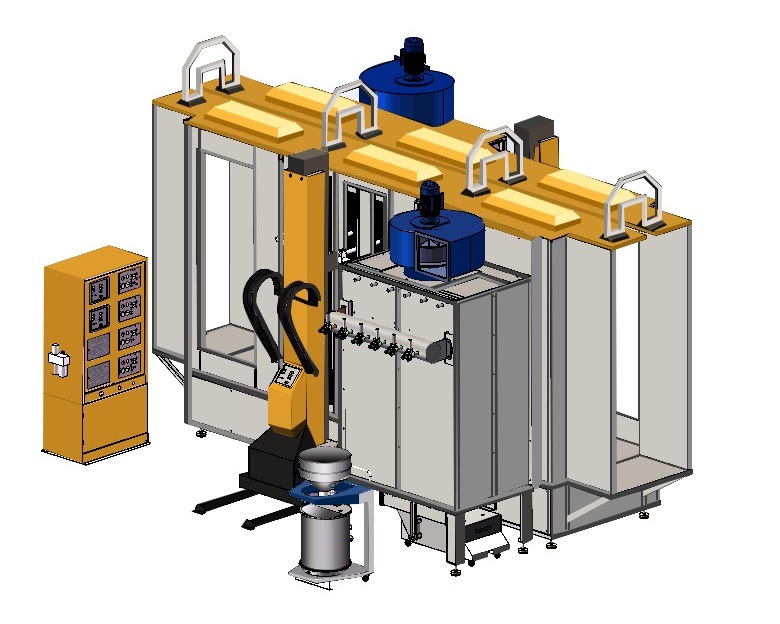

1. A central control cabinet combines all powder gun controller for integrated operation, space-saving and easy maintenance.

2. The 100kv spray gun powerfully charge powders for high transfer efficiency that saves powders a lot.

3. The COLO-800D Intelligent controller has one-touch preset buttons suitable for beginners handling different metal shapes, including panel-coating, corner-coating, re-coating.

4. The quantity of the control units installed in the cabinet can be customized as your production needs.

5. Based on COLO 15+ years technology, it is a proved reliable system with minimum maintenance.

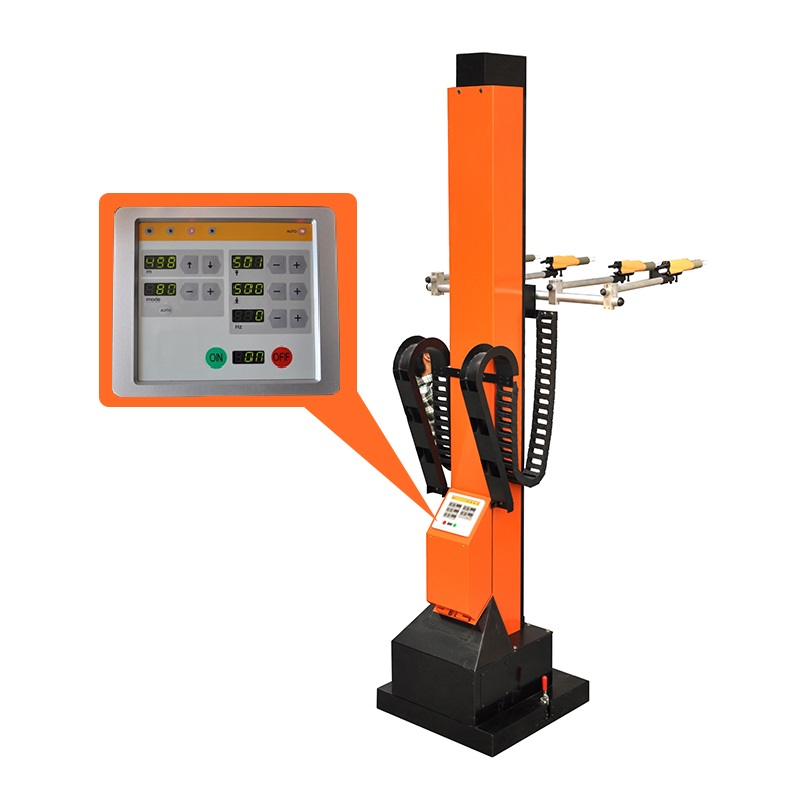

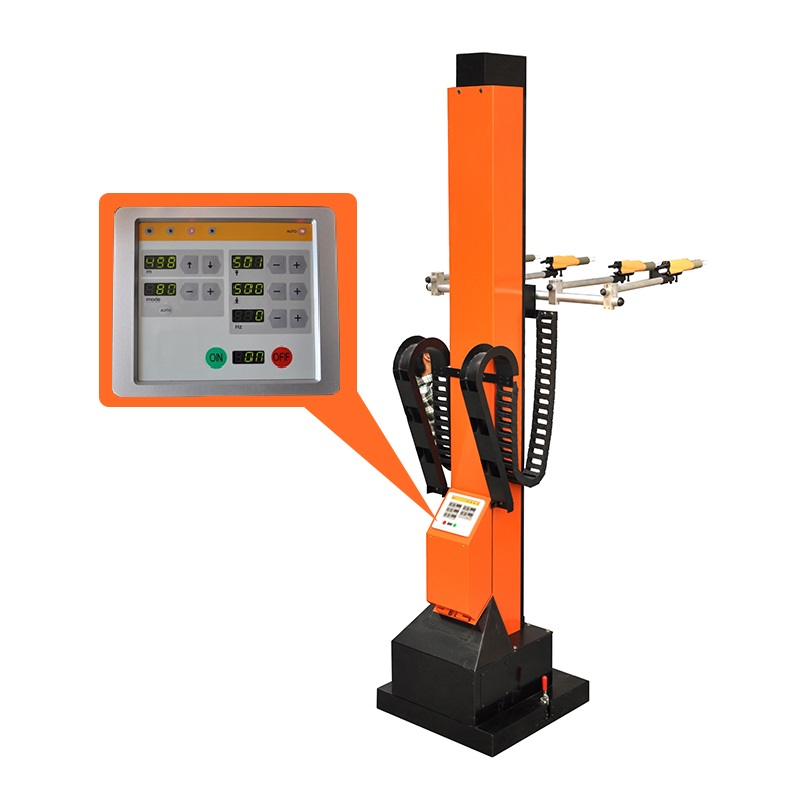

1.COLO Reciprocator is designed for consistent and uniform coating in automatic production line.

2.Spraying guns' movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

3.The digital control system can be memorized for 80 storable programs, Working parameters are monitored on a user-friendly panel,

4.Driven by frequency motor, solid and maintenance free. Allows to carry 2-12pcs spray gun, making smooth movement

5.Sturdy construction could adapt to continual load everyday operational conditions.

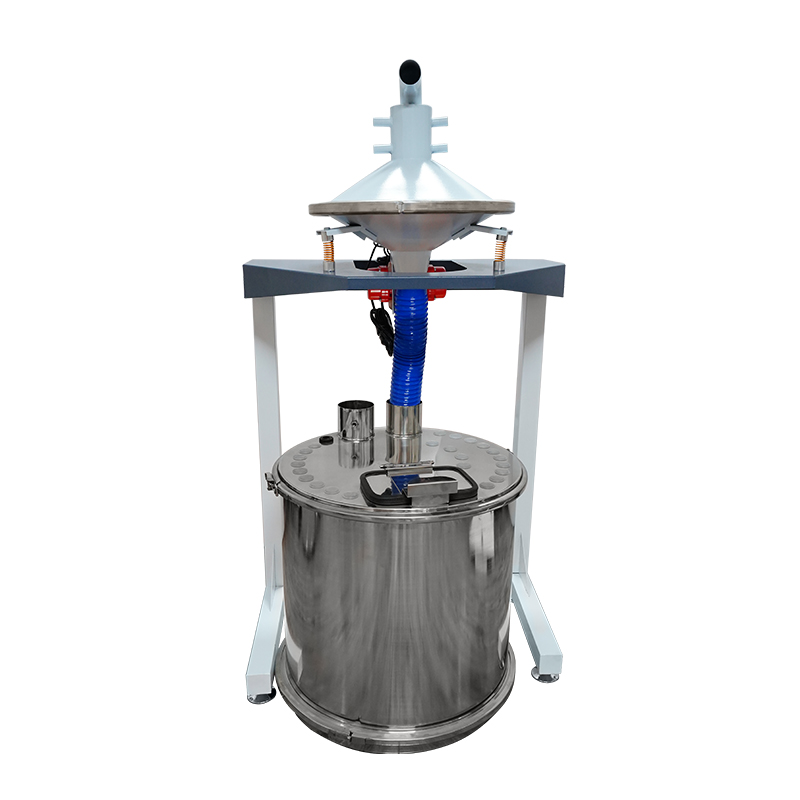

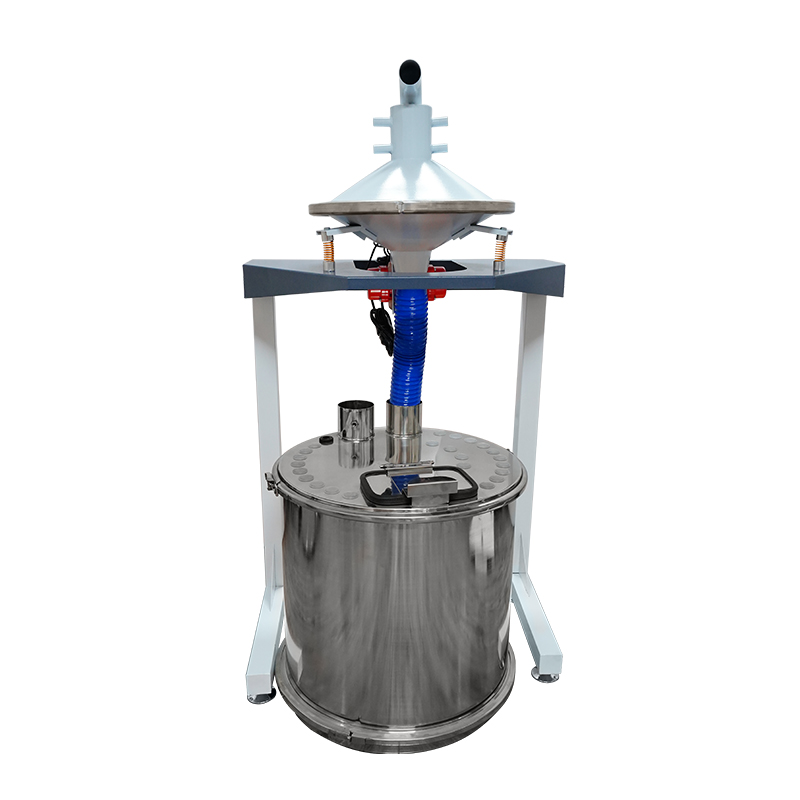

1.This powder sieving machine is connected in the automatic powder coating line, full automatic operations increases working efficiency.

2. Automatically feeding fresh powders and uniformly mixing with recycled powders, increases powder utilization.

3. Break powder accumulation, separate dusts and oversized, delivering pure and smooth powder flow which ensures application quality

4. The fully enclosed structure avoids dust leaking, features more environmentally friendly.

5. Space-saving size of powder sieving machine takes smaller area, and is easy to fit into limited space.

The system includes an automatic spray booth synchronously working with powder coating reciprocator, tailored automatic guns & control cabinets, conveyor system, which deliver best productivity and application quality in automatic production line.

Powder coating booth with spraying system a highly-efficient solution in automatic powder coating line. Reciprocators and automatic powder guns ensures productivity and uniformity, Automatic spray booth with powder recycling system creates clean working condition with high powder utilization rate. It is ideal for high production of aluminium profiles, steel plates, frames, metal furniture products with single color application.

1. Designed with double automatic station for reciprocator powder coating and double manual station for repair coating.

2. Two groups of cartridge filter ensures effective recovery of oversprayed powders.

3. Pulse-jet automatic filter cleaning technology takes full utilization of powders and extent filter life for many years.

4. All functions, parameters can be flexiblely controlled on the PLC panel, such as fan start, filter cleaning, booth cleaning.

5. Can be connected with powder management equipment for automatic powder recycling.

1. A central control cabinet combines all powder gun controller for integrated operation, space-saving and easy maintenance.

2. The 100kv spray gun powerfully charge powders for high transfer efficiency that saves powders a lot.

3. The COLO-800D Intelligent controller has one-touch preset buttons suitable for beginners handling different metal shapes, including panel-coating, corner-coating, re-coating.

4. The quantity of the control units installed in the cabinet can be customized as your production needs.

5. Based on COLO 15+ years technology, it is a proved reliable system with minimum maintenance.

1.COLO Reciprocator is designed for consistent and uniform coating in automatic production line.

2.Spraying guns' movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

3.The digital control system can be memorized for 80 storable programs, Working parameters are monitored on a user-friendly panel,

4.Driven by frequency motor, solid and maintenance free. Allows to carry 2-12pcs spray gun, making smooth movement

5.Sturdy construction could adapt to continual load everyday operational conditions.

1.This powder sieving machine is connected in the automatic powder coating line, full automatic operations increases working efficiency.

2. Automatically feeding fresh powders and uniformly mixing with recycled powders, increases powder utilization.

3. Break powder accumulation, separate dusts and oversized, delivering pure and smooth powder flow which ensures application quality

4. The fully enclosed structure avoids dust leaking, features more environmentally friendly.

5. Space-saving size of powder sieving machine takes smaller area, and is easy to fit into limited space.

The system includes an automatic spray booth synchronously working with powder coating reciprocator, tailored automatic guns & control cabinets, conveyor system, which deliver best productivity and application quality in automatic production line.